Email: hujin@chinahujin.cn

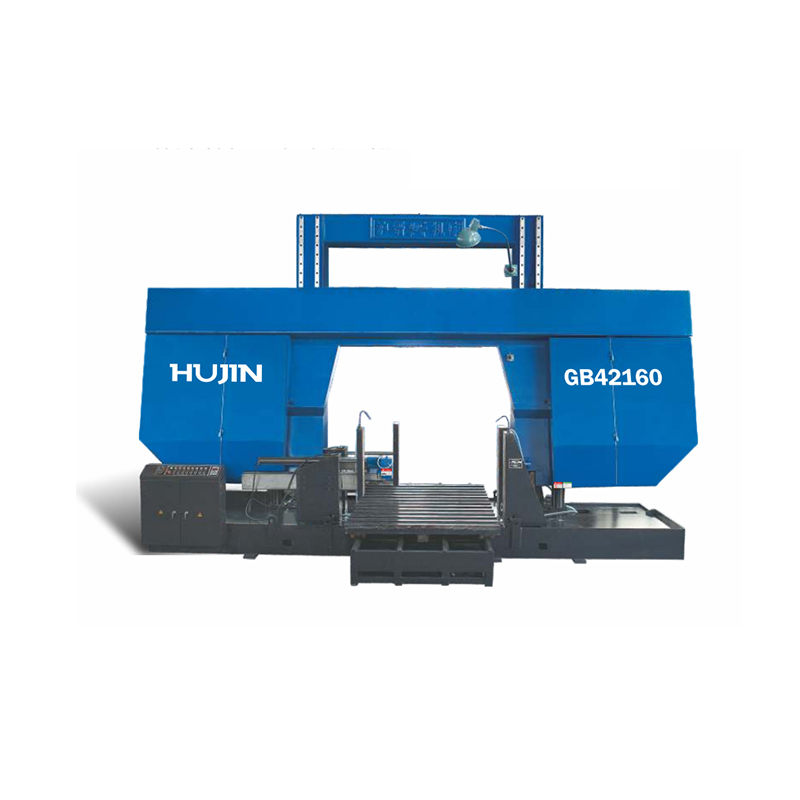

Durability of a Horizontal Band Saw Machine in Dusty or Humid Work Environments

Challenges Posed by Harsh Environmental Conditions

In many industrial settings, horizontal band saws are required to operate in less-than-ideal environments. These include areas with high humidity, frequent water exposure, or excessive dust from surrounding machinery and materials. Such conditions can significantly affect the overall durability and performance of the equipment. Moisture can cause corrosion of critical metal components, while dust can infiltrate moving parts and electrical systems, causing wear, clogging, or even mechanical failure. Therefore, evaluating how well a horizontal band saw machine can withstand these factors is essential for maintaining consistent production output and reducing downtime.

Construction Materials and Protective Coatings

The durability of a horizontal band saw in harsh environments begins with its construction. Machines that are built with corrosion-resistant materials such as stainless steel or treated cast iron are naturally better suited to withstand humid conditions. Additionally, high-quality models are often coated with anti-rust paint or powder coatings that provide an extra barrier against moisture and oxidation. These finishes help reduce the formation of rust on exposed surfaces and extend the machine’s lifespan even in environments where water spray or condensation is frequent. Machines lacking such protection may deteriorate rapidly if not maintained properly.

Sealing and Component Protection

Another important factor in the machine’s durability is how well its sensitive components are sealed or shielded. In dusty environments, fine particles can accumulate around motors, bearings, and hydraulic systems. If left unchecked, this buildup can cause overheating, poor lubrication, and premature failure of key components. To combat this, many modern machines incorporate sealed bearings, dust covers, and enclosures for electrical panels. Some advanced models also feature fan-cooled motors with filters or purging systems designed to resist airborne contaminants. In humid environments, sealed electrical connections and water-resistant enclosures are especially important for protecting the machine’s control systems.

Lubrication and Cooling System Reliability

Humidity and dust can also affect the machine’s lubrication and cooling systems. In high-moisture environments, lubricants may degrade more quickly, losing viscosity and effectiveness. This could cause increased friction and wear on the saw’s moving parts. Dust contamination in lubrication systems can also reduce performance and cause blockages. High-quality horizontal band saw machines are designed with centralized lubrication systems and integrated coolant management that help maintain proper fluid flow and reduce the risk of contamination. Regular inspection and cleaning of these systems are necessary to ensure continued durability in tough working conditions.

Suitability for Industrial Operations

Despite environmental challenges, many manufacturers produce horizontal band saw machines that are specifically engineered for rugged industrial use. These models are tested for resistance to moisture, dust, and other abrasive conditions, making them suitable for use in construction sites, shipyards, or outdoor fabrication shops. When properly selected and maintained, such machines can operate effectively for years, providing accurate and efficient cuts without frequent breakdowns. For companies operating in harsh environments, investing in a model with enhanced durability features can cause significant long-term cost savings.

Conclusion

The ability of a horizontal band saw machine to perform reliably in humid or dusty environments depends on several factors, including material quality, component sealing, system design, and regular maintenance. While challenging conditions can accelerate wear and tear, machines that are properly built and well-maintained can still offer good durability and consistent performance. Selecting a model designed with environmental resistance in mind ensures that the equipment remains a dependable asset, even in demanding industrial settings.

English

English русский

русский عربى

عربى