Email: hujin@chinahujin.cn

Evaluating the Work Efficiency of Small Bandsaw Machines in Various Applications

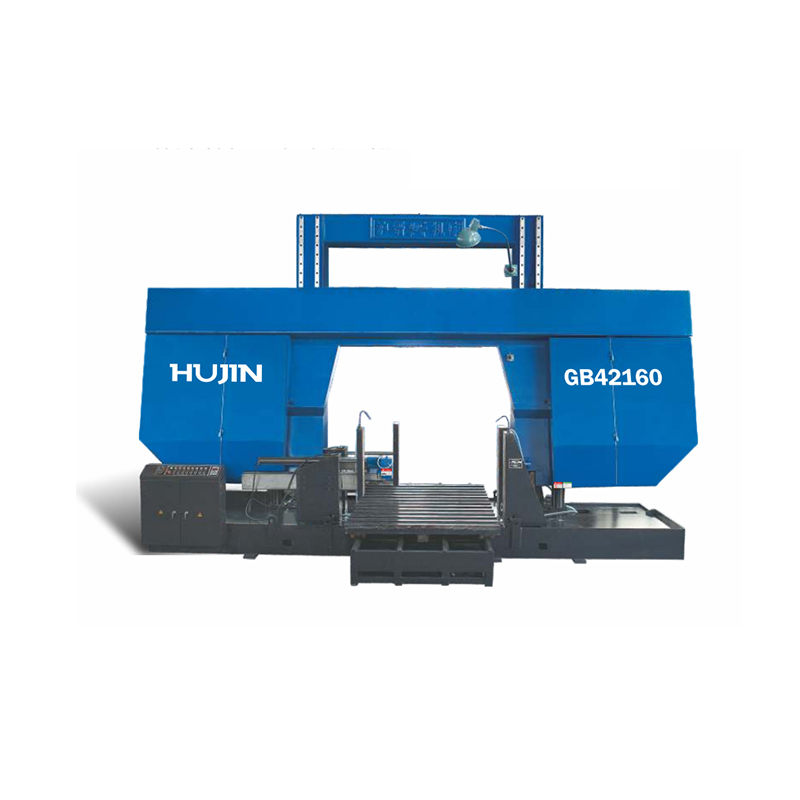

Sale China High Quality Small Bandsaw Machine Wholesaler

The small bandsaw machine, a staple in many workshops, is renowned for its versatility and precision. However, its efficiency in various work environments is a critical factor that can significantly impact productivity. This comprehensive examination will explore the efficiency of small bandsaw machines, considering their speed, power, and adaptability in different cutting scenarios.

Small bandsaw machines are designed to provide a balance between power and portability, making them ideal for both small-scale and large-scale projects. Their efficiency is often a result of several key factors, including the quality of the motor, the precision of the blade guidance system, and the overall design of the machine.

The motor of a small bandsaw machine is the heart of its operation, providing the necessary power to drive the blade through various materials. High-quality motors are essential for maintaining a consistent cutting speed, which is crucial for efficiency. A motor that can maintain its speed under load will ensure that the small bandsaw machine can cut through materials quickly and without stalling, thus increasing the overall work efficiency.

The blade guidance system is another critical component that affects the efficiency of a small bandsaw machine. Accurate and stable blade guidance ensures that the blade remains straight and true throughout the cutting process. This not only results in cleaner cuts but also reduces the likelihood of blade breakage or material wastage, both of which can significantly impact the efficiency of the machine.

The design of the small bandsaw machine itself also plays a role in its efficiency. A well-designed machine will have features that facilitate ease of use and quick setup. For instance, a machine with a quick-release blade tensioning system can save valuable time when changing blades, while a sturdy and stable frame ensures that the machine remains stable during operation, reducing the risk of accidents and improving the overall cutting process.

In terms of material handling, the efficiency of a small bandsaw machine can be greatly enhanced by the inclusion of features such as a work table that can be easily adjusted to accommodate different sizes and shapes of materials. This not only makes the machine more versatile but also allows for quicker setup and changeover times between projects.

The efficiency of a small bandsaw machine is also influenced by the type of blade used. A high-quality blade that is well-suited to the material being cut will result in faster cutting times and less wear on the machine. Additionally, the use of blade guides can help to keep the blade on track, reducing the need for frequent adjustments and ensuring a smooth, efficient cutting process.

Maintenance and upkeep of the small bandsaw machine are also crucial for maintaining its efficiency. Regular cleaning and lubrication of the machine's moving parts can help to prevent wear and tear, while sharp blades will cut more efficiently than dull ones. Investing time in proper maintenance can cause a longer lifespan for the machine and a more efficient cutting process.

In conclusion, the efficiency of a small bandsaw machine is a multifaceted concept that encompasses the machine's design, the quality of its components, and how it is used and maintained. By understanding these factors and taking steps to optimize them, users can ensure that their small bandsaw machines operate at good efficiency, delivering precise and quick cuts that enhance productivity and satisfaction in the workshop.

English

English русский

русский عربى

عربى