Email: hujin@chinahujin.cn

Performance Evaluation of Automatic Vertical Band Saws in Cutting Various Materials

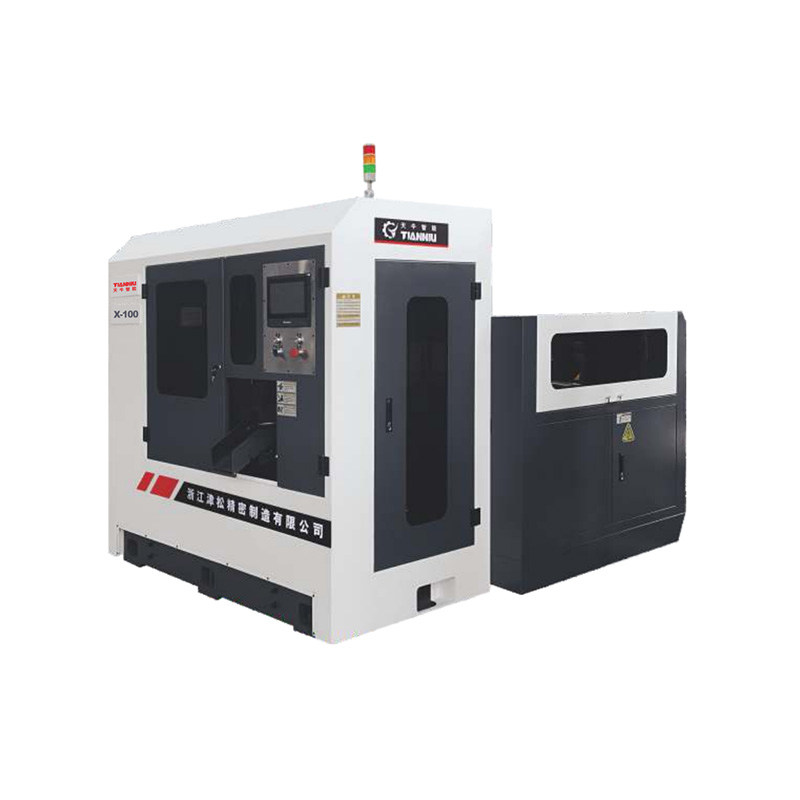

Design Automatic Vertical Band Saw Manufacturer in China

The Automatic Vertical Band Saw stands as a stalwart in the field of material processing, renowned for its precision and efficiency in cutting a wide array of materials. This article aims to explore the performance characteristics of the Automatic Vertical Band Saw when faced with the challenge of cutting different materials, from metals to plastics, and everything in between.

The Automatic Vertical Band Saw's performance is a testament to its versatility and adaptability. Its ability to handle various materials with ease is a direct result of its sophisticated design and engineering. The saw's cutting capacity is not only a function of its mechanical components but also of the advanced control systems that govern its operations.

When it comes to cutting metals, the Automatic Vertical Band Saw excels due to its robust construction and powerful motor. The saw's ability to maintain a consistent cutting speed and feed rate ensures that it can handle tough materials like steel and aluminum with precision. The use of high-quality blades specifically designed for metal cutting further enhances the saw's performance, reducing the risk of blade breakage and ensuring clean, burr-free cuts.

In contrast, when the Automatic Vertical Band Saw is tasked with cutting softer materials such as wood or plastic, it demonstrates a different set of advantages. The saw's variable speed control allows for gentler cutting, which is crucial for preventing damage to softer materials. The precision of the Automatic Vertical Band Saw also means that it can produce intricate cuts and detailed designs that would be challenging to achieve with a manual band saw.

The Automatic Vertical Band Saw's performance is also influenced by the quality of its blade guides and tensioning systems. These components ensure that the blade remains straight and true throughout the cutting process, regardless of the material being cut. This is particularly important when dealing with materials that are prone to warping or that have an irregular shape.

One of the significant advantages of the Automatic Vertical Band Saw over manual band saws is its ability to maintain a consistent cutting angle. This consistency is crucial for achieving accurate and repeatable cuts, especially when working with materials that require precision, such as aerospace-grade alloys or high-strength plastics.

The Automatic Vertical Band Saw's performance is also enhanced by its automation capabilities. The saw can be programmed to cut specific patterns or follow complex contours, which is particularly useful when cutting materials that are difficult to handle manually. This automation not only improves the saw's performance but also increases worker safety by reducing the need for direct contact with the cutting blade.

In terms of cutting speed, the Automatic Vertical Band Saw outperforms manual band saws by a significant margin. The saw's high-speed cutting capabilities allow for faster production times, which is especially beneficial when working with large volumes of material. This speed, combined with the saw's precision, results in a higher quality of cut and less material waste.

Maintenance and blade life are also critical factors in the performance of the Automatic Vertical Band Saw. Regular maintenance ensures that the saw remains in suitable condition, which directly impacts its cutting performance. The saw's blade life is extended by its precision cutting and the use of high-quality blades, which can withstand the rigors of cutting various materials without dulling quickly.

In conclusion, the Automatic Vertical Band Saw's performance in cutting various materials is a result of its advanced design, precision engineering, and automation capabilities. It offers a good cutting experience compared to manual band saws, providing clean, accurate cuts across a wide range of materials. The Automatic Vertical Band Saw's ability to adapt to different materials and cutting requirements makes it an indispensable tool in modern material processing.

English

English русский

русский عربى

عربى