Email: hujin@chinahujin.cn

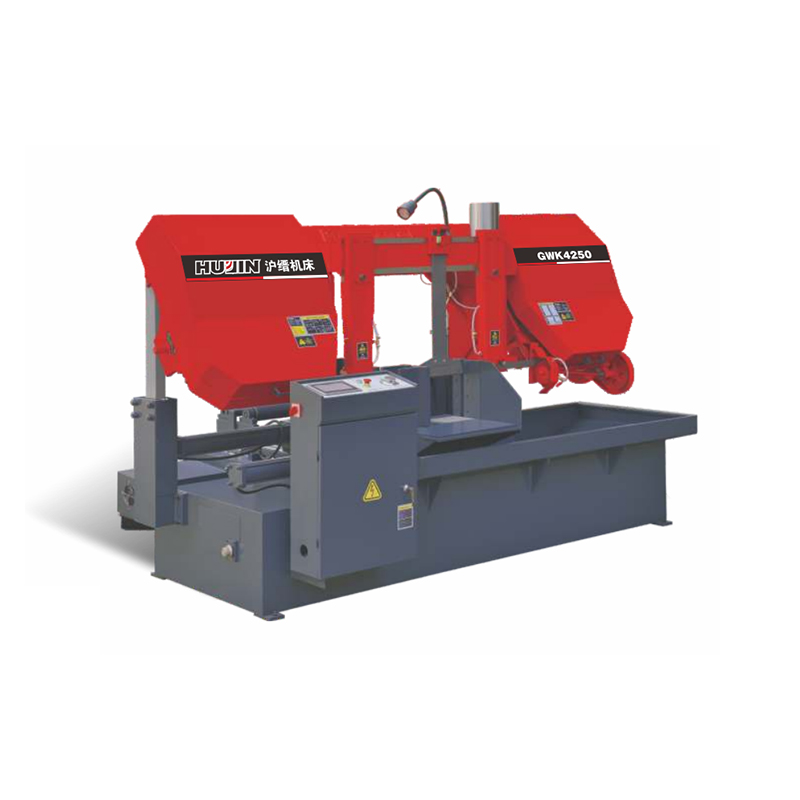

Performance of Double Column Band Saw Factory Cutting Various Materials

Versatility in Material Cutting

Double-column band saws are widely used in industrial settings due to their ability to handle a variety of materials, including steel, aluminum, and alloys. A Double Column Band Saw Factory designs machines to accommodate the differing mechanical properties, hardness, and thermal characteristics of these materials. Understanding how the saw performs across these materials is essential for ensuring precision, efficiency, and long-term durability.

Cutting Performance on Steel

Steel is one of the common materials processed by double-column band saws. Due to its hardness and density, cutting steel requires careful control of blade speed, feed rate, and tension. The saw must maintain stable blade alignment to prevent wandering and ensure clean, accurate cuts. High-quality steel blades with suitable tooth geometry are necessary to resist wear and maintain cutting performance. A robust machine frame with sufficient rigidity is critical to handle the resistance offered by steel while reducing vibrations that could reduce precision or damage the blade. Proper coolant application is also vital to reduce heat buildup, which can cause blade deformation and affect the surface finish of the steel.

Cutting Performance on Aluminum

Aluminum, being softer and less dense than steel, requires different cutting parameters. Blade speed is typically higher, and feed rates can be increased without compromising accuracy. Aluminum’s lower hardness reduces blade wear, but its ductility can cause material to stick to the blade if the tooth geometry is not optimized. The double column design offers stability, allowing the saw to maintain straight cuts over long workpieces without deflection. Coolants are used differently with aluminum, mainly to remove chips and prevent accumulation, rather than for extensive heat dissipation. Overall, the machine’s versatility allows it to switch between steel and aluminum with minor adjustments in settings and tooling.

Cutting Performance on Alloys

Alloys present a unique challenge because their properties vary widely depending on composition. Some alloys are harder than steel, while others are more prone to heat sensitivity or surface damage. The performance of a double-column band saw depends on selecting the correct blade material and tooth configuration, as well as adjusting cutting speed and feed rate to match the alloy’s properties. A stable machine frame ensures vibration during cutting, which is essential for alloys with high hardness or toughness to prevent chipping and maintain dimensional accuracy. Coolants play a crucial role in preventing overheating, which can alter the microstructure of heat-sensitive alloys and compromise their integrity.

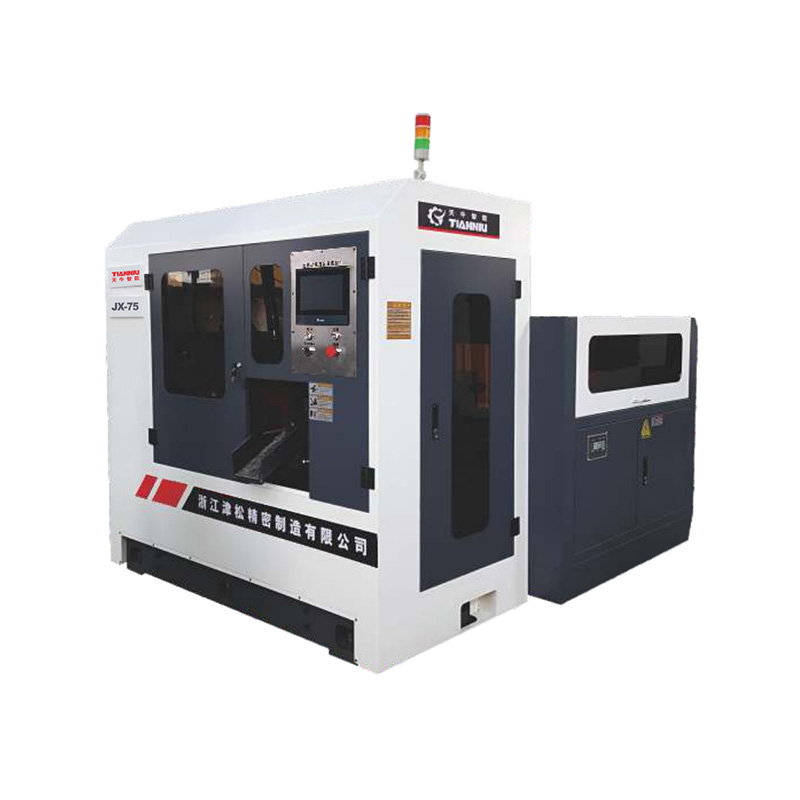

Machine Design and Adaptability

A Double Column Band Saw Factory focuses on building machines that are adaptable to different materials. Blade guides, tensioning systems, and feed mechanisms are designed to handle variations in cutting resistance. The dual-column structure provides increased rigidity, reducing deflection and vibration regardless of the material being cut. The ability to adjust blade speed, feed rate, and cooling methods allows operators to optimize performance for each specific material type, improving efficiency and extending the lifespan of both the blade and the machine.

Optimizing Performance Across Materials

The performance of double-column band saws varies according to the material being processed. Steel requires careful management of blade tension, speed, and cooling to handle its hardness. Aluminum allows faster cutting but demands attention to chip removal and blade geometry. Alloys present a spectrum of challenges requiring precise adjustments to speed, feed, and cooling. By designing machines with adaptability, rigidity, and precise control systems, a Double Column Band Saw Factory ensures that its saws deliver reliable, accurate, and efficient cutting across steel, aluminum, and alloy workpieces. This versatility is essential for modern industrial applications, where multiple material types must be processed with downtime and precision.

English

English русский

русский عربى

عربى