Email: hujin@chinahujin.cn

Hydraulic and Servo Feed Systems in Horizontal Band Saw Machine Operation

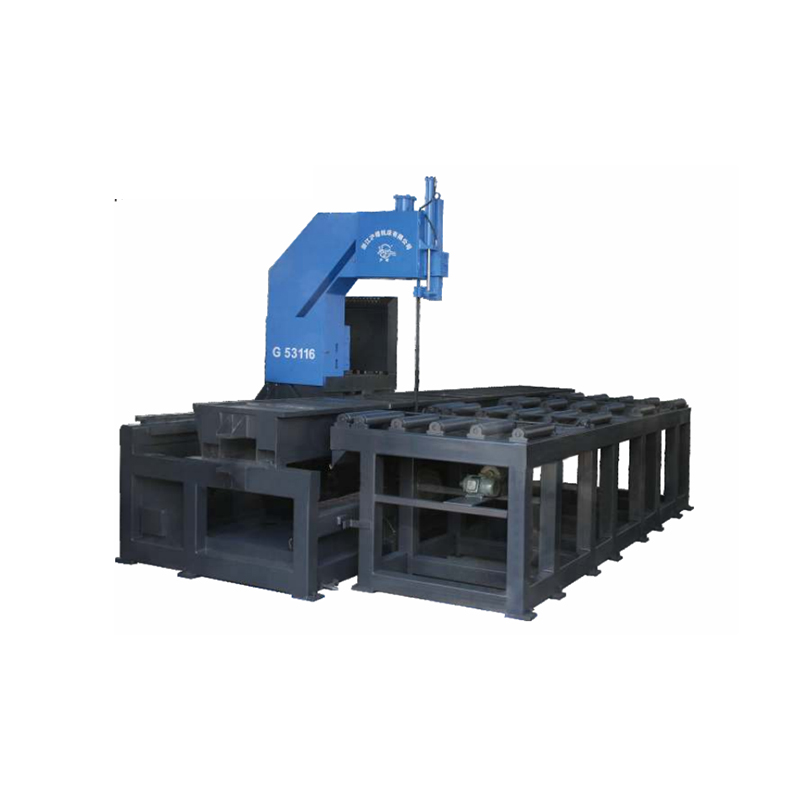

The feed system of a Horizontal Band Saw Machine plays a critical role in determining cutting efficiency, accuracy, and overall performance. Modern machines typically use either hydraulic or servo-driven feed mechanisms to control the downward motion of the saw blade onto the workpiece. These systems influence cutting speed, force consistency, and adaptability to different materials, making them essential for achieving suitable results in both industrial and precision applications.

Hydraulic Feed System Overview

Hydraulic feed systems utilize pressurized fluid to drive the movement of the saw head. By regulating fluid flow, operators can adjust the downward force applied to the workpiece, allowing for consistent cutting even with varying material densities. One of the primary advantages of hydraulic systems is their ability to provide smooth, continuous feed under heavy loads. This ensures that the blade maintains stable contact with the material, reducing vibration and improving cut quality. Hydraulic feeds are also highly reliable in high-production environments due to their durability and tolerance for heavy-duty operations.

Servo Feed System Overview

Servo feed systems, in contrast, employ electric servo motors to control the saw’s movement. These systems allow for precise positioning and speed adjustments with a high degree of repeatability. Servo-driven feeds are particularly beneficial for high-precision cutting tasks where exact control of feed rate and blade position is necessary. They provide the flexibility to program different feed profiles for varying materials, optimizing both speed and accuracy. Additionally, servo systems often integrate with CNC controls, enabling automated operations and more complex cutting sequences.

Comparison of Hydraulic and Servo Systems

While both systems aim to optimize feed performance, their characteristics differ. Hydraulic systems excel in heavy-duty cutting, offering robust force and smooth operation under variable load conditions. They are less sensitive to external factors such as temperature fluctuations and provide consistent performance over extended periods. Servo feed systems, however, prioritize precision, offering rapid response, programmable control, and deviation in cutting speed. Operators may choose between systems depending on whether the priority is production speed, precision, or a balance of both.

Impact on Cutting Performance

The feed system directly affects blade engagement and material removal rates. In a hydraulic system, the feed force adapts automatically to resistance, reducing the risk of blade deflection or damage when cutting hard or irregular materials. Servo systems, by contrast, provide exact feed control that ensures uniform chip formation and precise edge quality, which is critical for applications requiring tight tolerances. Proper integration of these systems with blade selection and machine rigidity further enhances cutting efficiency and surface finish.

Maintenance and Operational Considerations

Hydraulic systems require regular inspection of fluid levels, seals, and pressure settings to maintain consistent performance. Contaminated or degraded hydraulic fluid can cause uneven feed force and potential system failure. Servo systems necessitate monitoring of motor performance, encoder accuracy, and software calibration. Both systems benefit from routine maintenance, but servo drives may demand more specialized technical expertise due to their electronic and programmable components.

The feed system of a Horizontal Band Saw Machine—whether hydraulic or servo-driven—significantly influences cutting quality, speed, and adaptability. Hydraulic systems provide smooth, reliable performance in heavy-duty applications, while servo systems offer precise, programmable control for high-accuracy cutting. Understanding the strengths and limitations of each system allows operators to select the suitable feed mechanism for specific production goals, ensuring both efficiency and high-quality results in metalworking operations.

English

English русский

русский عربى

عربى