Email: hujin@chinahujin.cn

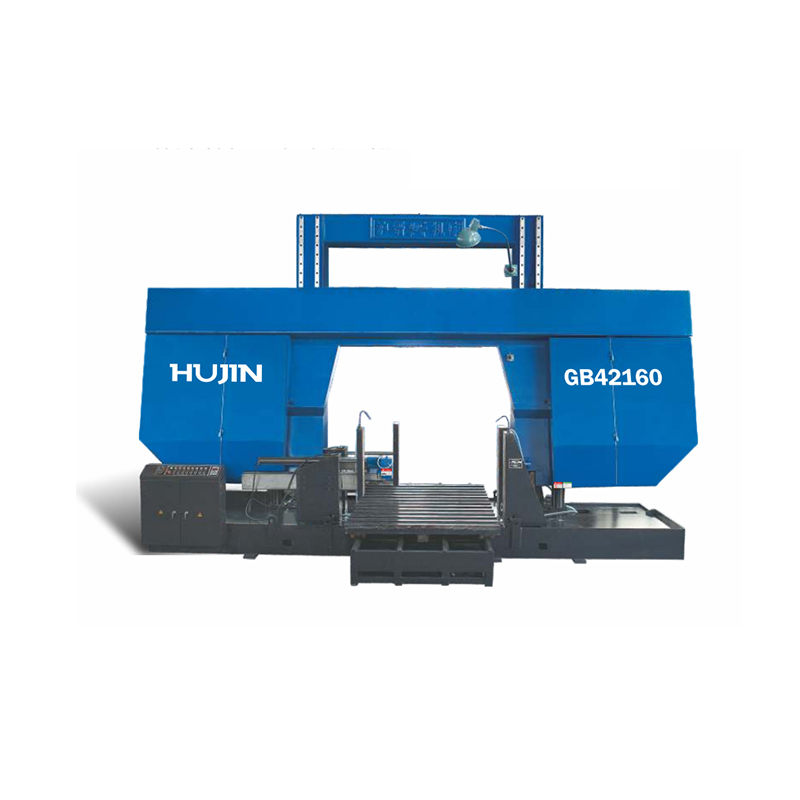

Burr Formation and Edge Quality in Horizontal Band Saw Machine Cutting .

The quality of a cut directly affects downstream processes and product performance. One common issue in band saw cutting is the formation of burrs or uneven edges, which can require additional finishing operations. Understanding the factors that contribute to burr formation and edge irregularities in a Horizontal Band Saw Machine is essential for maintaining efficiency, reducing waste, and achieving high-quality results.

Causes of Burr Formation

Burrs are small, raised edges or fragments of material that form during the cutting process. They typically occur when the cutting forces are uneven or the blade cannot fully shear the material. Factors such as blade sharpness, tooth geometry, feed rate, and material hardness all play significant roles. Inconsistent feed pressure or worn blade teeth can result in rough edges and small protrusions, which may compromise dimensional accuracy and aesthetics.

Influence of Blade Selection

The type of blade used in a Horizontal Band Saw Machine significantly affects edge quality. Coarse-tooth blades, while suitable for high-speed cutting and rapid material removal, tend to produce more burrs on softer metals. Conversely, fine-tooth blades provide smoother cuts but may require slower feed rates and careful handling to avoid overheating. Material-specific blade selection, including carbide-tipped or high-speed steel blades, helps reduce burr formation while maintaining efficiency.

Cutting Parameters and Machine Settings

Cutting speed, feed rate, and blade tension are critical parameters that influence edge quality. Excessive feed rates can push the blade through the material too quickly, causing tearing or irregular edges. Insufficient blade tension can cause blade wander, vibration, and inconsistent cuts, increasing the likelihood of burrs. Properly calibrated speeds and feeds, combined with stable clamping of the workpiece, reduce edge imperfections and ensure straight, clean cuts.

Material Considerations

Different metals respond differently to band saw cutting. Hard alloys may resist shearing, increasing the potential for rough edges or minor burrs. Soft metals, such as aluminum or copper, may deform or pull during cutting, causing ragged edges. Understanding the material’s properties and adjusting cutting parameters accordingly is essential to achieving smooth, consistent edges. Additionally, using appropriate coolant or lubrication can reduce friction and heat, further improving edge quality.

Role of Machine Maintenance

Well-maintained Horizontal Band Saw Machines produce more consistent and precise cuts. Worn bearings, misaligned blade guides, or a dull blade can contribute to uneven edges and burr formation. Regular inspection, cleaning, and replacement of critical components, along with proper blade sharpening, are key practices to reduce edge defects and maintain suitable cutting performance.

Post-Cutting Finishing

Despite optimization, some burrs or edge irregularities may still occur, especially in high-production or hard-metal applications. Deburring or secondary finishing processes, such as grinding or filing, may be necessary to meet stringent quality requirements. However, reducing the occurrence of burrs at the cutting stage decreases labor, time, and costs associated with post-processing.

The occurrence of burrs and uneven edges in Horizontal Band Saw Machine cutting is influenced by blade selection, machine settings, material characteristics, and maintenance practices. By carefully choosing blades, optimizing cutting parameters, and maintaining the machine, operators can achieve high-quality cuts with edge defects. Understanding these factors ensures improved productivity, reduced post-processing, and consistent results in metalworking applications

English

English русский

русский عربى

عربى