Email: hujin@chinahujin.cn

Maintaining Long-Term Stability in Heavy-Duty Dual-Column Sawing Systems

Understanding Stability Requirements

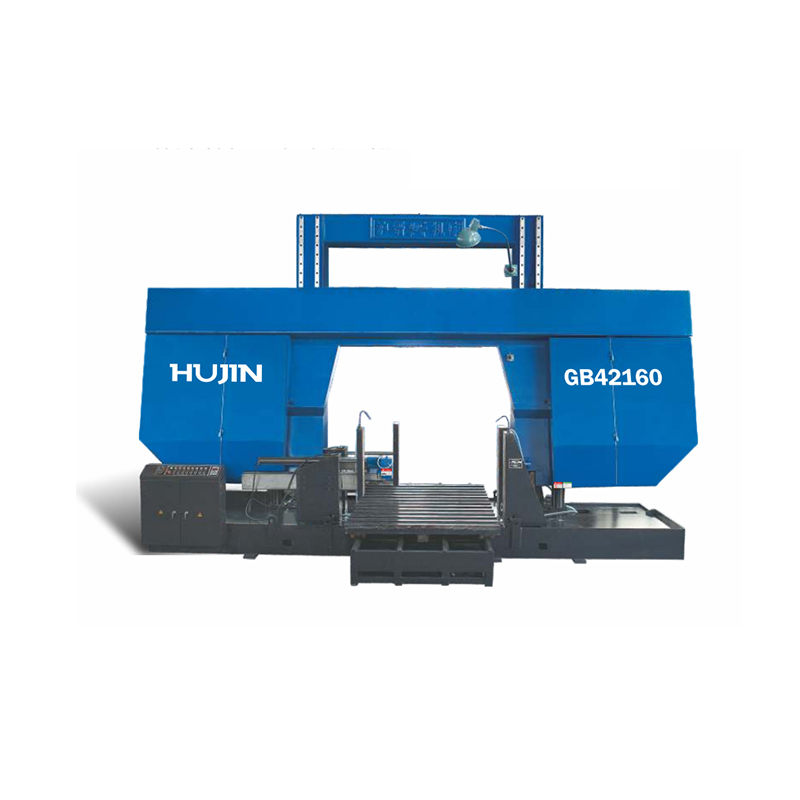

In industrial cutting environments, maintaining long-term operational stability is crucial for achieving precise cuts, improving productivity, and reducing machine wear. Many users looking to acquire equipment from a Double Column Band Saw Factory want to ensure that the machine remains consistent over years of continuous operation. A double-column band saw is often selected for its rigidity and ability to handle large, tough materials such as steel billets, structural beams, and alloy rods. However, the core concern lies in how such machines preserve their structural and functional stability when operating for extended periods, often under high cutting forces and intensive workloads. Understanding the design principles, engineering techniques, and maintenance practices that support long-term stability allows users to make informed decisions and properly manage these machines in demanding workshop environments.

Robust Column Structure and Frame Engineering

One of the important factors contributing to long-term stability is the robust dual-column frame structure. In a design provided by modern Double Column Band Saw Factory facilities, the two parallel guide pillars offer balanced support to the saw bow, preventing tilting or vibration during cutting. The rigid steel columns undergo precision machining and heat treatment processes to enhance stiffness and reduce internal stress. This structural rigidity allows the machine to maintain alignment even after thousands of cutting cycles. Alongside the frame, reinforced bed designs are integrated to absorb vibration and resist external forces produced by large-diameter workpieces. Combined, these mechanical elements form the foundation for sustained cutting accuracy and reduced deformation.

Hydraulic and Guide System Precision

Another key factor influencing long-term stability is the guide and hydraulic system design. High-quality roller or carbide guides hold the blade firmly, limiting lateral movement and preventing premature blade wear. Advanced hydraulic tensioning systems control blade tension consistently, ensuring continuous cutting force without fluctuations that could compromise precision. Many systems include automatic blade pressure adjustment, which optimizes feeding force according to material hardness and thickness. These engineering features help extend blade life, maintain cutting accuracy, and reduce energy waste over prolonged operation.

Lubrication, Cooling, and Vibration Control

Stability is further supported by efficient lubrication and cooling systems that reduce heat buildup and reduce mechanical resistance. Continuous lubrication of guide rails, bearings, and moving components prevents wear and maintains smooth motion. Cooling systems using soluble oils or emulsions dissipate heat generated during high-speed cutting, reducing thermal stress on both the blade and the machine body. To counter vibration, dampening pads, precision alignment mechanisms, and high-grade bearings are incorporated, ensuring that continuous operation does not result in incremental loss of accuracy or machine fatigue.

Maintenance Strategy and Operator Practices

Technical design alone is not enough; long-term stability also relies on proper maintenance and operation. Routine inspection of guide rails, hydraulic pumps, blade tensioners, and lubrication lines prevents minor issues from escalating. Blade selection, proper feeding speed adjustment, and correct material positioning reduce wear and mechanical strain. Operators trained in suitable cutting parameters, alignment adjustment, and coolant management maintain the machine's performance and extend its lifecycle. Modern control systems also include alarm functions and monitoring features that notify operators when abnormal vibration, blade load, or temperature conditions occur, supporting preventive maintenance practices.

Engineering and Management for Continuous Reliability

Long-term stability in double column band saw machines results from a combination of precision structural design, advanced hydraulic and guide mechanisms, efficient lubrication and cooling systems, and disciplined operator maintenance. When engineering from a Double Column Band Saw Factory meets proper usage and care, the machine can deliver years of accurate, efficient, and reliable cutting performance. For industrial environments where consistent output and material quality are essential, selecting a well-engineered dual-column band saw and applying comprehensive maintenance protocols ensures dependable operation and lasting system integrity.

English

English русский

русский عربى

عربى