Email: hujin@chinahujin.cn

Metal Versus Wood Cutting With Angle Cut Band Saw

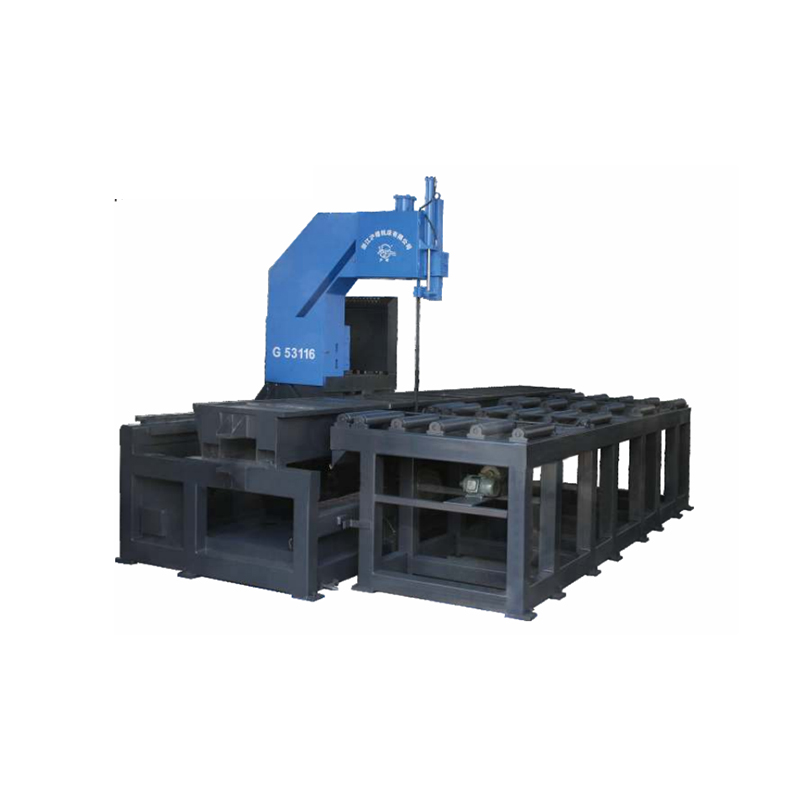

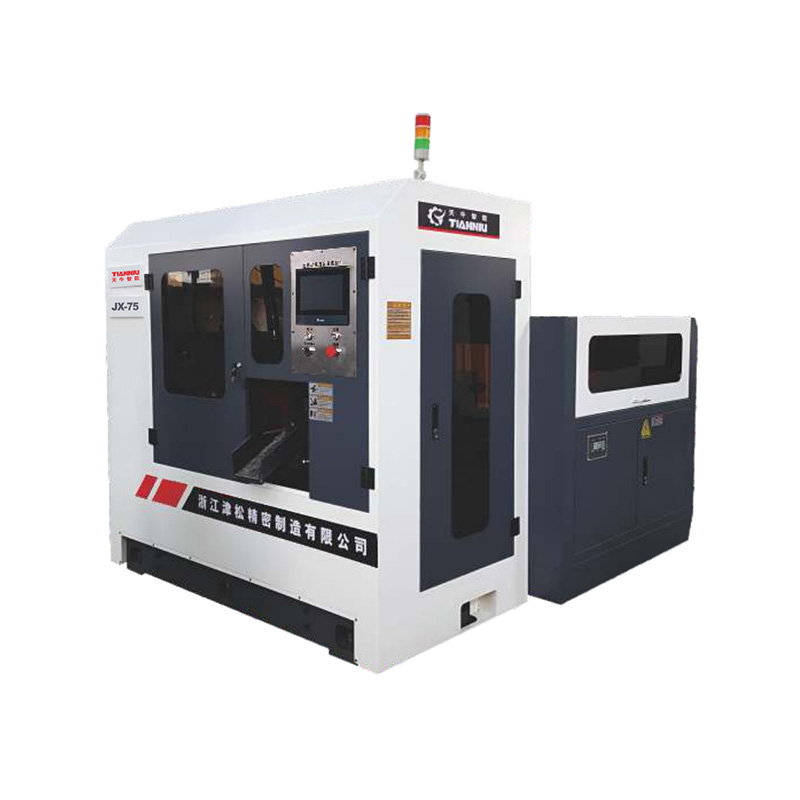

An Angle Cut Band Saw is a versatile machine designed to perform precise angled cuts on a variety of materials. Its ability to adjust the cutting angle makes it a preferred choice in metalworking and woodworking shops. However, its performance can vary significantly depending on the material being cut. Understanding the differences in how an Angle Cut Band Saw handles metal and wood is essential for operators to optimize efficiency, accuracy, and tool longevity.

Cutting Metal: Challenges and Capabilities

When cutting metal, an Angle Cut Band Saw must handle hardness, density, and heat generation. Metals such as steel, aluminum, and brass require strong, durable blades and consistent motor power to maintain cutting speed without stalling. The blade teeth, pitch, and material selection are critical for ensuring smooth cuts. Metal cutting produces more friction and heat, which can reduce blade life if the saw is not properly maintained. Cooling systems, such as mist or flood coolant, are often used to reduce heat buildup and prevent warping or damage to both the blade and the workpiece. Precision is key in metal cutting, and the saw must maintain a steady feed rate and accurate angle to achieve consistent results.

Cutting Wood: Speed and Flexibility

In contrast, cutting wood with an Angle Cut Band Saw generally requires less power and generates less heat, allowing for faster cuts. Wood is more forgiving, which means that the saw can handle higher feed rates without risking blade damage. Different types of wood, such as hardwoods and softwoods, still affect cutting speed and quality, but the machine experiences less stress compared to metal cutting. Wood cutting also allows more flexibility in blade selection, with options designed for fine finishes or rough cuts depending on the application. Operators can achieve smooth, clean, angled cuts quickly, making the saw suitable for furniture, cabinetry, and construction tasks.

Blade Considerations for Different Materials

The Angle Cut Band Saw uses different blade types for metal and wood. Metal cutting blades are typically made from high-speed steel (HSS) or bi-metal with smaller, evenly spaced teeth designed to handle hardness and heat. Wood cutting blades often have larger teeth and a different tooth geometry to remove material efficiently without overheating. Choosing the correct blade for the material is critical to maintain cut quality and prolong blade life. Switching between metal and wood requires careful adjustment of blade speed, tension, and feed rate to optimize performance for each material.

Operational Differences

Operators must also adjust the machine settings depending on whether they are cutting metal or wood. Metal cutting requires slower feed rates, continuous lubrication or coolant, and steady pressure to prevent blade damage and ensure precise cuts. Wood cutting allows faster feed rates, minimal lubrication, and more aggressive cutting techniques. The Angle Cut Band Saw’s ability to maintain a precise cutting angle is equally important for both materials, but the operator’s attention to material-specific adjustments is key to achieving the results.

An Angle Cut Band Saw performs differently when cutting metal versus wood due to variations in material hardness, density, and heat generation. Metal cutting demands slower feed rates, strong blades, and cooling systems, while wood cutting allows faster operation and greater flexibility in blade selection. Understanding these differences and making proper adjustments to blade type, speed, and feed ensures suitable performance, accuracy, and longevity of the saw. By adapting to the material, operators can improve the capabilities of an Angle Cut Band Saw across both metalworking and woodworking applications.

English

English русский

русский عربى

عربى