Email: hujin@chinahujin.cn

Adjusting Blade Tension for Optimal Band Saw Performance

Importance of Proper Blade Tension

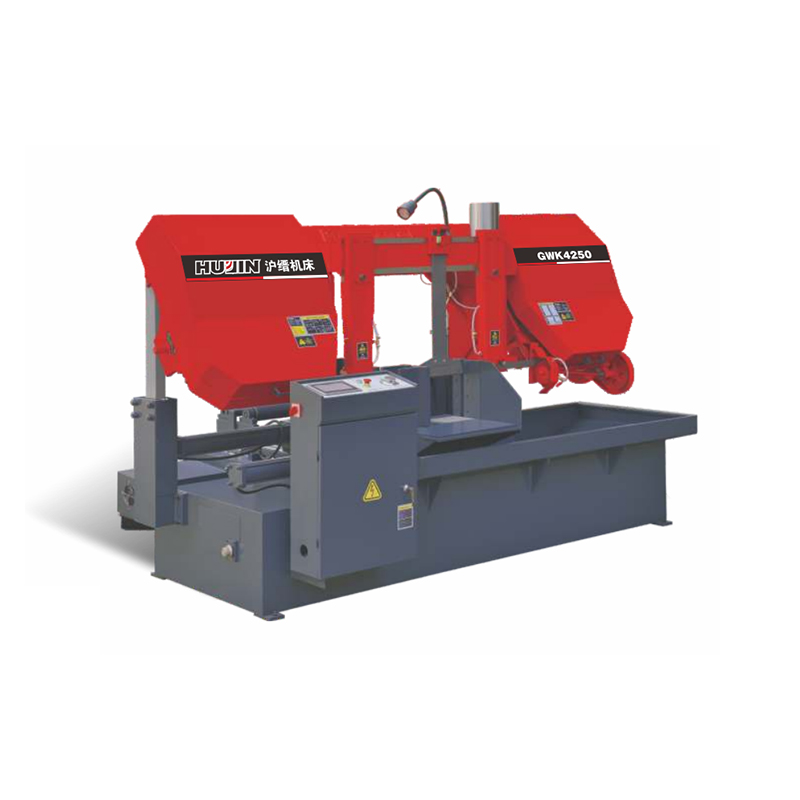

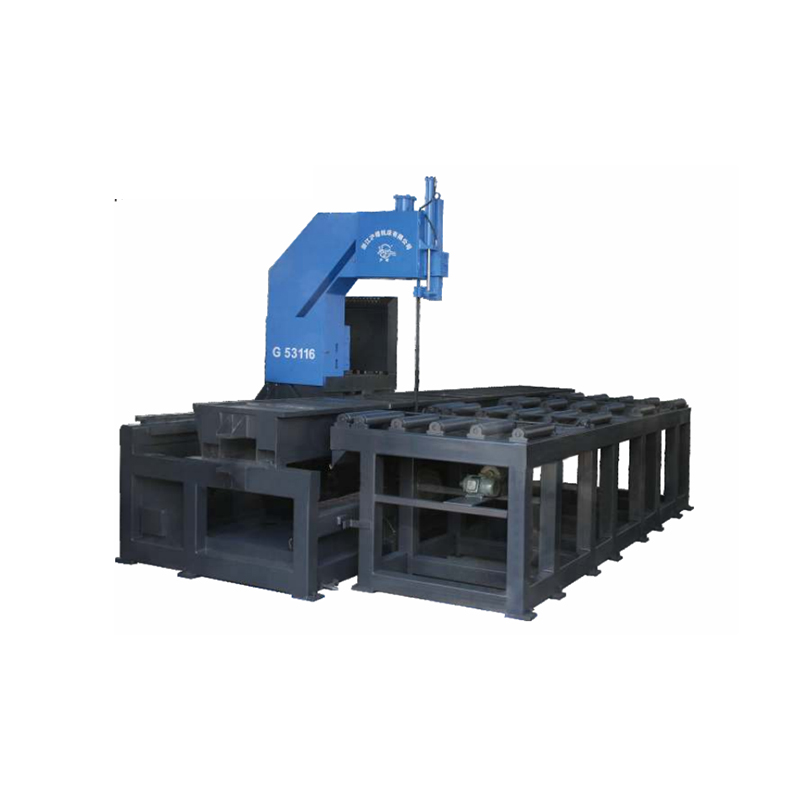

A Double Column Band Saw relies on precise blade tension to maintain cutting accuracy, prolong blade life, and ensure operator safety. Improper tension, whether too loose or too tight, can cause uneven cuts, premature blade wear, or even catastrophic failure. In high-precision metal cutting applications, small deviations in tension can translate into dimensional inaccuracies, material wastage, and increased operational costs. Therefore, understanding how to correctly adjust blade tension is fundamental to achieving both suitable performance and extended equipment longevity.

Effects of Over-Tensioning the Blade

Applying excessive tension to a band saw blade may initially appear to improve cutting stability, but it can have detrimental effects over time. Over-tensioned blades are subjected to higher stress, which accelerates fatigue and can cause teeth to break or the blade to snap. Additionally, the saw’s guide bearings and pulleys experience increased load, causing faster wear of critical components. Excessive tension can also distort the frame slightly, reducing the smoothness of blade travel and compromising cut quality. Recognizing these risks highlights why tension must be carefully calibrated rather than improved arbitrarily.

Consequences of Under-Tensioning

Conversely, insufficient blade tension can result in a blade that wanders during cutting, producing inaccurate and rough cuts. An under-tensioned blade may vibrate excessively, causing uneven tooth engagement and accelerated wear on both the blade and the workpiece. Such vibrations can transmit stress to the machine frame and guide systems, potentially causing long-term alignment issues. Material edges may become jagged, and operators may find themselves constantly correcting cuts, reducing overall efficiency. Maintaining proper tension ensures the blade runs smoothly, producing precise cuts consistently.

Methods for Adjusting Blade Tension

Modern Double Column Band Saws are typically equipped with mechanical or hydraulic tensioning systems. Mechanical systems allow operators to adjust tension manually using calibrated scales, screws, or springs, while hydraulic systems use controlled pressure to maintain consistent tension automatically. For either system, it is essential to refer to the manufacturer’s recommended tension settings, which are often based on blade width, thickness, and the type of material being cut. Checking tension with a gauge or measuring device ensures that the adjustment falls within a suitable range, preventing both over- and under-tensioning.

Monitoring Tension During Operation

Tension should not only be set before cutting but also monitored throughout extended operations. Heat generated during cutting can slightly alter tension, and long continuous cuts may require periodic adjustments to maintain suitable performance. Observing the blade for signs of excessive vibration, drift, or unusual noise can provide early indications that tension has changed. Regular inspection and minor adjustments help maintain cutting accuracy and reduce the risk of blade failure.

Benefits of Correct Blade Tension

Maintaining proper blade tension delivers multiple benefits: improved cut quality, longer blade life, reduced wear on machine components, and safer operation. A well-tensioned blade ensures consistent engagement with the material, reducing deviations and producing smooth, accurate cuts. By avoiding excessive stress or slack, operators reduce downtime and replacement costs, increasing overall productivity. Correct tensioning also enhances machine reliability, allowing a Double Column Band Saw to perform at its designed capacity over an extended service life.

Precision and Longevity Through Tension Control

Blade tension is a critical factor in the performance of a Double Column Band Saw. By understanding the risks of over- and under-tensioning, following manufacturer recommendations, and monitoring blade behavior during operation, operators can achieve precise, high-quality cuts while improving blade and machine longevity. Proper tension management is an investment in both operational efficiency and long-term equipment reliability.

English

English русский

русский عربى

عربى