Email: hujin@chinahujin.cn

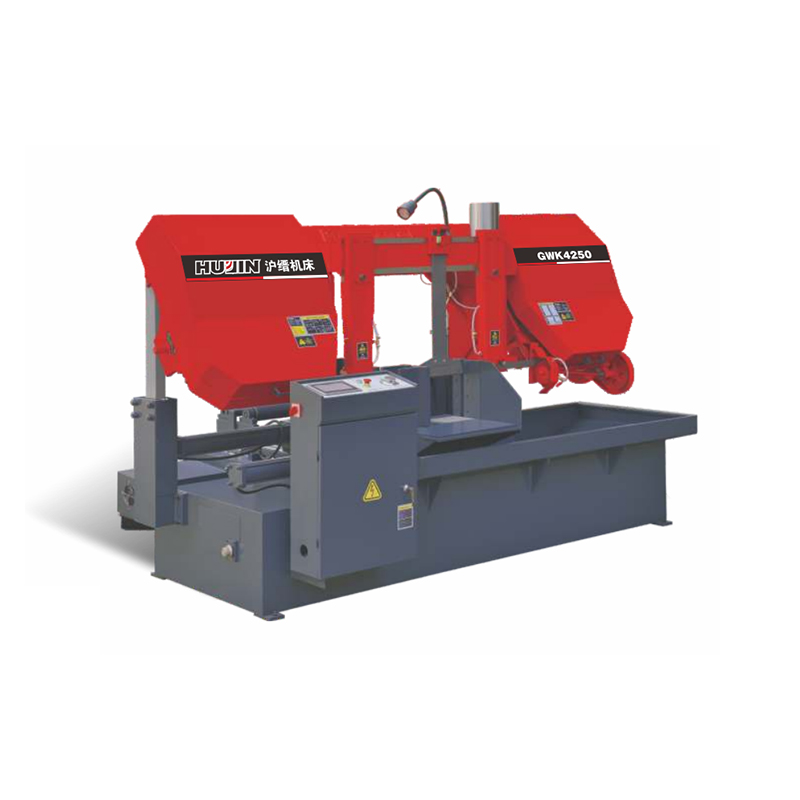

Assessing Safety Features and Emergency Mechanisms in Horizontal Band Saw Machine Design

Safety is a critical concern in any metalworking environment, and the design of a Horizontal Band Saw Machine must prioritize operator protection. These machines involve high-speed moving blades, powerful motors, and heavy workpieces, all of which can pose significant hazards if proper safety measures are not implemented. Understanding the safety features, including protective guards and emergency stop mechanisms, is essential for ensuring both operator well-being and operational efficiency.

Importance of Protective Guards

Protective guards are fundamental components of any band saw machine, designed to physically separate operators from moving parts. In a Horizontal Band Saw Machine, guards typically cover the blade, pulley system, and other rotating components. These guards prevent accidental contact with sharp edges and moving parts, reducing the risk of cuts, entanglement, or other serious injuries. Modern designs often incorporate adjustable guards to accommodate different material sizes while maintaining comprehensive coverage around the cutting area.

Emergency Stop Mechanisms

Emergency stop devices are another essential aspect of safety design. These mechanisms allow operators to immediately halt machine operation in case of unexpected issues, such as blade binding, material slippage, or any potential hazard in the work area. Emergency stops are usually positioned within easy reach, often at multiple points around the machine, to ensure quick access. Advanced machines may also integrate electronic interlocks, which automatically shut down the blade when a guard is opened or when sensors detect unsafe conditions.

Additional Safety Features

Beyond guards and emergency stops, many Horizontal Band Saw Machines include additional safety features to further protect operators. These can include blade tracking indicators to prevent derailment, limit switches to control feed range, and anti-kickback systems to stabilize workpieces during cutting. Some machines also offer two-hand control systems, requiring simultaneous activation of buttons to prevent accidental operation. Safety signage and clearly marked operating zones contribute to creating a safer working environment.

Operator Training and Practices

Even with advanced safety features, proper training remains crucial. Operators must understand machine controls, safe loading and clamping techniques, and emergency procedures. Consistent use of personal protective equipment, including gloves, safety glasses, and hearing protection, complements built-in safety measures. Routine safety checks, such as inspecting guards, testing emergency stops, and verifying blade tension, help maintain suitable protection over time.

Maintenance and Safety Integration

Maintenance directly affects machine safety. Worn or misaligned guards, malfunctioning emergency stops, or loose components can compromise operator protection. Regular inspection, cleaning, and replacement of safety-related parts are necessary to ensure the machine’s safety mechanisms function reliably. Integrating safety checks into maintenance routines not only prevents accidents but also prolongs the life of the equipment.

Compliance with Safety Standards

Many Horizontal Band Saw Machines are designed to meet international safety standards, such as ISO or CE certifications. Compliance ensures that the machine has been tested for hazards, incorporates essential protective features, and follows recommended safety practices. Choosing a machine that adheres to these standards assures that safety has been systematically addressed in the design.

The safety features of a Horizontal Band Saw Machine, including protective guards, emergency stop devices, and additional safety mechanisms, are essential for protecting operators from injury. Proper integration of these features, combined with operator training, maintenance, and adherence to safety standards, ensures a secure and efficient cutting environment. By prioritizing safety in both machine design and operation, manufacturers and users can reduce risks while improving productivity and reliability in metalworking applications.

English

English русский

русский عربى

عربى