Email: hujin@chinahujin.cn

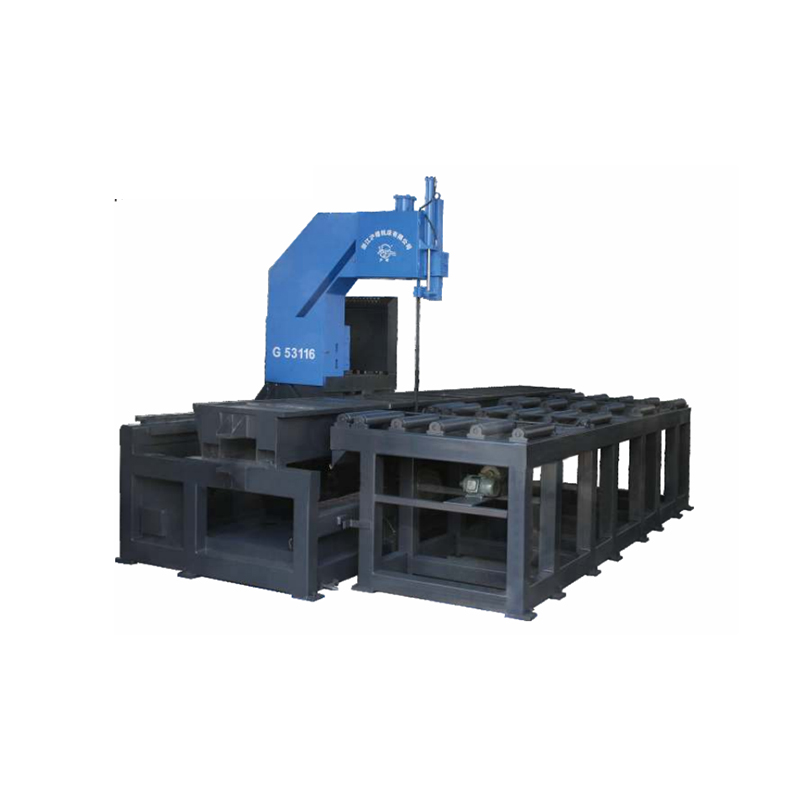

Evaluating the Suitability of Vertical Band Saws for Machining Irregularly Shaped Materials

Introduction to Cutting Irregular Shapes with Vertical Band Saw

One of its standout features is its ability to cut irregularly shaped materials with precision. Unlike traditional saws that are typically designed for straight cuts, the Vertical Band Saw offers the flexibility to handle complex, non-linear shapes, making it a preferred choice for many industries. Whether in woodworking, metalworking, or custom fabrication, its design and operational flexibility allow it to adapt to a wide range of cutting challenges, particularly those that involve intricate shapes and curves.

Flexibility in Material Feeding and Cutting Motion

A key advantage of the Vertical Band Saw in cutting irregularly shaped materials is the vertical orientation of the saw blade. This design allows the operator to manually guide the workpiece through the blade, providing a high degree of control over the cutting path. Unlike horizontal band saws, which typically require straight-line cuts, it allows for more intricate maneuvering. The operator can adjust the position of the material during the cutting process, making it easier to navigate around curves, angles, and other irregularities in the material.

Precise Cuts on Curved and Complex Shapes

The Vertical Band Saw is particularly effective when it comes to cutting curved or complex shapes. This capability is vital in industries where products are often custom-made, such as furniture manufacturing, sign making, or even automotive parts fabrication. The operator can adjust the angle of the material to achieve precise, smooth cuts along irregular lines. This level of control makes it an ideal choice for cutting intricate curves and detailed patterns that would be difficult or impossible with other types of saws.

Blade Selection for Irregular Materials

The versatility of the Vertical Band Saw is further enhanced by its ability to accommodate various types of blades. For cutting irregular materials, operators can choose from a wide range of blade types with different tooth configurations. Finer-toothed blades are good for making detailed cuts in materials such as wood or plastics, while coarser blades can be used for tougher materials like metal. By selecting the appropriate blade for the material and the desired cut, it ensures clean, accurate cuts, even when dealing with complex shapes.

Control and Precision for Complex Cuts

When working with irregularly shaped materials, control and precision are essential. The Vertical Band Saw offers good control over the material compared to other saws. Because the operator manually feeds the material into the blade, they can make real-time adjustments, ensuring that the cut stays true to the desired path. This level of hands-on control is particularly beneficial when cutting intricate details or when precision is critical to the overall integrity of the piece. In addition, the Vertical Band Saw typically allows for more precise adjustments to the cutting speed, ensuring suitable results on different materials.

Versatility in Material Types

The ability to cut irregularly shaped materials isn't limited to one type of material. The Vertical Band Saw is versatile enough to handle a variety of materials, from soft woods to tough metals and composites. Its ability to handle both large and small workpieces, along with its capacity to cut curves and angles, makes it suitable for industries that require complex, customized components. Whether you're working with a large sheet of metal or a small, irregularly shaped piece of wood, it adapts to the job, providing consistent, high-quality cuts.

Conclusion

The Vertical Band Saw is a highly effective tool for cutting irregularly shaped materials with accuracy and precision. Its design, which allows for manual material feeding and greater control, makes it good for tasks that involve curves, angles, and detailed patterns. The ability to select different blades for various materials further enhances its versatility. Whether in woodworking, metalworking, or custom fabrication, it offers a reliable solution for cutting complex shapes and ensuring that the final product meets high standards.

English

English русский

русский عربى

عربى