Email: hujin@chinahujin.cn

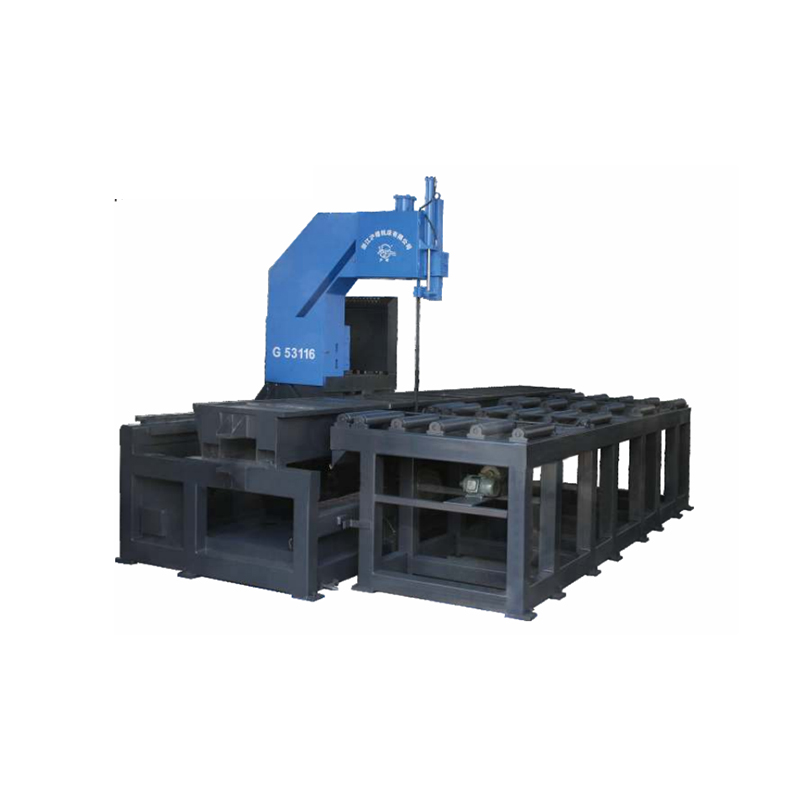

Preventing Hydraulic Leakage in Double Column Band Saw

Importance of Hydraulic System Integrity

The hydraulic system in a Double Column Band Saw is essential for controlling the movement of the saw head, feed mechanism, and clamping system. Maintaining its integrity is critical because any leakage can cause loss of pressure, inconsistent operation, reduced cutting precision, and potential safety hazards. Understanding the causes of hydraulic leakage and implementing preventative measures ensures the machine operates efficiently and reliably.

High-Quality Components and Seals

One of the effective ways to prevent leakage is the use of high-quality components and seals. Hydraulic hoses, valves, cylinders, and connectors must meet strict manufacturing standards to withstand pressure fluctuations and long-term operation. Seals, including O-rings and gaskets, should be designed for the specific type of hydraulic fluid and operating temperatures. Selecting components from reputable suppliers reduces the likelihood of premature wear or material degradation, which are common causes of leakage in hydraulic systems.

Proper Installation and Alignment

Even high-quality hydraulic components can fail if improperly installed. Correct alignment of cylinders and hydraulic lines is critical to reduce stress and prevent leakage at connection points. Misaligned cylinders can cause uneven pressure on seals, causing early failure. Proper torque on fittings, secure mounting of hoses, and careful routing of lines to avoid sharp bends or interference with moving parts all contribute to a reliable, leak-free hydraulic system.

Regular Maintenance and Inspection

Routine maintenance is a key factor in preventing hydraulic leakage in a Double Column Band Saw. Periodic inspection of hoses, fittings, and seals allows operators to detect wear, cracks, or other potential issues before they result in leaks. Monitoring hydraulic fluid levels and checking for contamination also ensures the system remains in a suitable condition. Scheduled replacement of high-stress components, even before visible damage occurs, significantly reduces the risk of unexpected leakage during operation.

Contamination Control and Fluid Management

Hydraulic fluid quality directly affects seal performance and overall system integrity. Contaminants such as dirt, metal particles, or water can degrade seals and corrode components, causing leaks. Implementing effective filtration systems and using clean, manufacturer-recommended hydraulic fluid helps maintain system reliability. Additionally, controlling fluid temperature within the recommended range prevents thermal expansion or degradation of seals, further reducing the risk of leakage.

Pressure Regulation and System Design

Proper hydraulic system design, including pressure regulation, plays a crucial role in preventing leaks. Overpressure can damage seals, fittings, and cylinders, while underpressure may cause improper operation. Pressure relief valves, accumulators, and flow control devices help maintain stable operating conditions, protecting both the machine and its hydraulic components. A well-designed system tailored to the specific load and cutting requirements of a Double Column Band Saw ensures consistent performance without undue stress on the hydraulic system.

Preventing hydraulic leakage in a Double Column Band Saw requires a combination of high-quality components, precise installation, regular maintenance, contamination control, and proper system design. By focusing on these factors, manufacturers and operators can ensure reliable, safe, and efficient operation of the hydraulic system. Maintaining hydraulic integrity not only improves cutting accuracy and machine performance but also extends the service life of the equipment, making it a critical aspect of industrial band saw management.

English

English русский

русский عربى

عربى