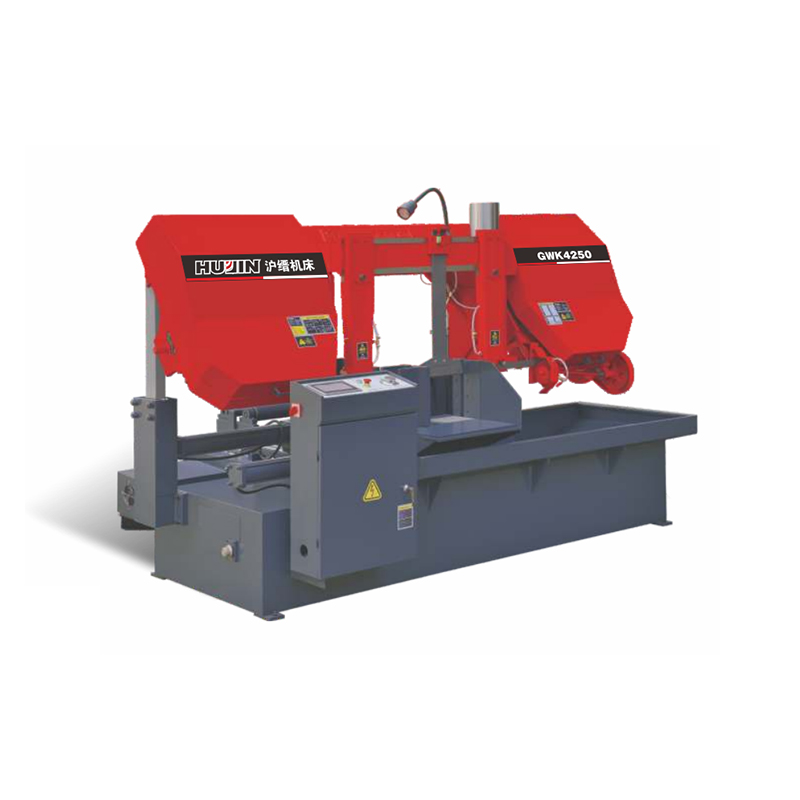

Email: hujin@chinahujin.cn

Proven Methods to Significantly Reduce Blade Wear in Automatic Band Saw Machines

In metal cutting operations, the blade or saw band is one of the critical components of an Automatic Band Saw Machine. It's wear directly affects cutting accuracy, surface finish, and overall operational costs. Frequent blade replacement can increase downtime and maintenance expenses, so reducing blade wear is essential for improving efficiency and extending blade life. This article explores the key methods and practices to reduce wear on band saw blades during automatic cutting processes.

Selecting the Appropriate Blade Material and Tooth Geometry

Choosing the right blade material is fundamental in controlling wear. High-quality blades made of bi-metal, carbide-tipped, or cobalt alloys offer enhanced hardness and heat resistance compared to standard carbon steel blades. These materials withstand abrasion and maintain sharp cutting edges longer, especially when cutting hard metals. Additionally, tooth geometry affects cutting efficiency and wear. Blades with optimized tooth pitch, hook angle, and set pattern reduce cutting forces and heat generation, thereby decreasing wear. For example, finer tooth pitches are better suited for thin or hard materials, distributing cutting loads more evenly.

Maintaining Proper Blade Tension and Tracking

Proper blade tension is crucial to reducing wear and preventing premature failure. If the blade is too loose, it can deflect or vibrate during cutting, causing uneven wear and tooth damage. Conversely, excessive tension can cause blade cracking. Modern automatic band saw machines often include automatic tensioning systems that maintain consistent blade tension throughout operation, compensating for thermal expansion and mechanical stress. Alongside tension, blade tracking—ensuring the saw band stays aligned on the wheels—is vital to prevent rubbing against guides or frame components, which accelerates wear.

Effective Cooling and Lubrication Systems

Heat is a primary factor in blade wear. Friction at the cutting interface generates heat, softening the blade material and reducing its lifespan. To mitigate this, efficient cooling and lubrication systems are integrated into automatic band saw machines. Delivering coolants directly to the cutting zone reduces temperature, flushes away chips, and lubricates the blade teeth. Proper coolant selection and maintenance help prevent buildup or corrosion, both of which can increase friction and wear. Consistent cooling also preserves blade hardness, maintaining sharp cutting edges longer.

Optimizing Cutting Parameters for Reduced Wear

Adjusting operational parameters such as feed rate, cutting speed, and blade speed significantly impacts blade life. Excessively high speeds or aggressive feeds cause increased heat and mechanical stress, hastening wear. Conversely, too slow speeds can cause the blade to rub rather than cut efficiently. Finding a suitable balance tailored to the material type and thickness ensures efficient cutting with blade degradation. Many automatic band saw machines allow programmable cutting parameters and adaptive control systems that adjust settings in real time to maintain ideal cutting conditions.

Regular Maintenance and Timely Blade Inspection

Preventive maintenance is essential to reduce blade wear. Operators should routinely inspect blades for signs of tooth damage, cracking, or dullness. Cleaning the blade and guide systems of metal chips and debris prevents abrasive wear. Checking guide rollers, bearings, and wheels for wear or misalignment also protects the blade from unnecessary friction. Replacing worn parts and keeping the machine properly lubricated ensures smooth operation, reducing blade strain. Documenting maintenance schedules and blade usage helps plan timely blade changes before failure occurs.

English

English русский

русский عربى

عربى