Email: hujin@chinahujin.cn

Cooling Media Commonly Used in Automatic Band Saw Machines

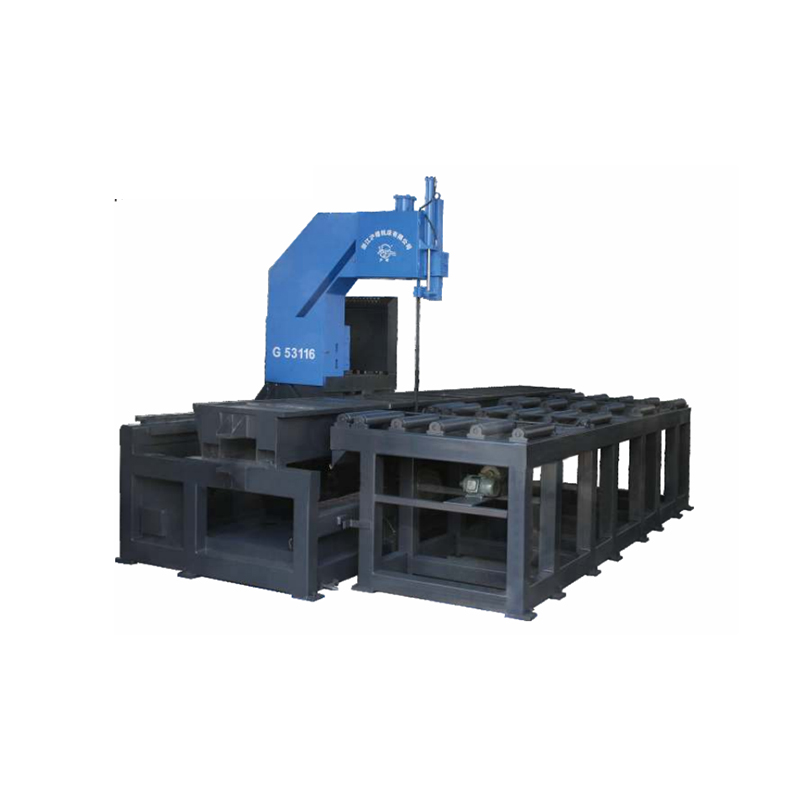

The Automatic Band Saw Machine is an essential tool in metalworking industries, prized for its ability to cut through various metals quickly and accurately. During operation, significant heat is generated at the cutting interface due to friction between the blade and the material. Efficient cooling is critical to maintain cutting performance, extend blade life, and ensure operator safety. This article examines the different types of cooling media commonly used in automatic band saw machines and the advantages and considerations associated with each.

Water-Based Coolants: The Common Choice

Water-based coolants are the widely used cooling media in automatic band saw machines. Typically formulated as emulsions or soluble oils mixed with water, these coolants provide good heat dissipation due to water’s high specific heat capacity. Their fluidity allows them to quickly absorb and carry away heat generated during cutting. Additionally, water-based coolants often contain additives to prevent corrosion, reduce bacterial growth, and improve lubricity. These properties help protect both the blade and the workpiece from damage. The relatively low cost and ease of use make water-based coolants the default choice for many applications, especially when cutting ferrous metals.

Oil-Based Coolants for Enhanced Lubrication

Oil-based coolants, including neat oils or semi-synthetic formulations, offer good lubrication compared to water-based coolants. They form a thin film on the cutting blade and material, reducing friction and wear. This lubrication is particularly beneficial when cutting harder metals or alloys that generate intense heat and cause rapid blade degradation. While oil-based coolants do not cool as efficiently as water-based media, their enhanced lubricating properties can improve cutting surface quality and prolong blade life. These coolants are often used in precision cutting environments or when specific materials require extra lubrication.

Synthetic Coolants for Specialized Applications

Synthetic coolants are chemically engineered fluids that do not contain petroleum or mineral oils. They provide good cooling and lubricating characteristics while being less prone to bacterial contamination or residue buildup. These coolants are often formulated to meet environmental and health regulations, making them a preferred choice in eco-conscious manufacturing facilities. Synthetic coolants tend to have a longer service life and require less maintenance. However, they are generally more expensive and may need specific disposal procedures.

Air and Mist Cooling: Alternative Methods

Besides liquid coolants, some automatic band saw machines utilize air or mist cooling systems. Air cooling blows compressed air directly onto the cutting zone, helping to remove heat and debris without introducing liquids. This method is useful when coolant contamination of the workpiece must be avoided, such as in certain medical or food industry applications. Mist cooling combines air with a fine spray of coolant, offering some lubrication and cooling benefits with reduced fluid use. While these methods reduce cleanup and corrosion issues, they are typically less effective in heat dissipation compared to liquid coolants and are suited to lighter cutting tasks.

Factors Influencing Cooling Media Selection

Choosing the right cooling medium depends on several factors, including the material being cut, cutting speed, machine design, and environmental considerations. Water-based coolants excel in general-purpose cutting and high-volume production. Oil-based coolants are favored for heavy-duty or high-precision cutting tasks requiring good lubrication. Synthetic coolants provide a balance between performance and environmental impact, while air or mist cooling suits specialized, contamination-sensitive operations. Proper coolant maintenance, including concentration control and filtration, is essential regardless of the medium to ensure consistent performance and machine longevity.

English

English русский

русский عربى

عربى