Email: hujin@chinahujin.cn

Strategies for Maintaining Cutting Precision and Stability in High-Speed Band Saw Machines

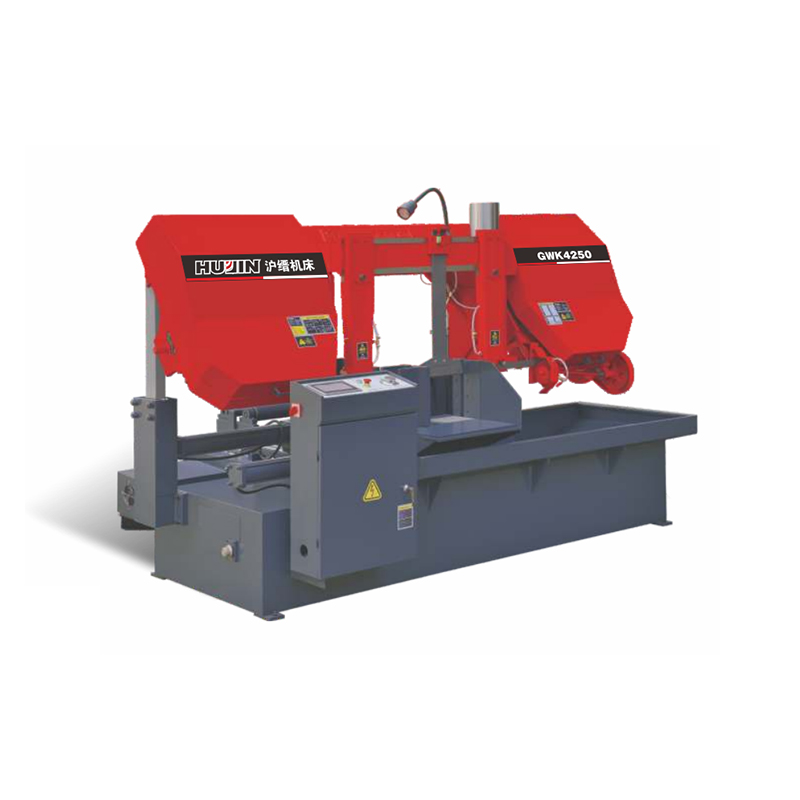

In modern manufacturing, the Automatic Band Saw Machine plays a critical role in delivering efficient and precise metal cutting. High-speed operation is essential for productivity, but it also brings challenges related to machine stability. Maintaining stability at elevated speeds is crucial to avoid inaccuracies, excessive wear, and operational hazards. This article explores the key design features and control methods that enable automatic band saw machines to run smoothly and reliably under high-speed conditions.、

Robust Frame and Structural Rigidity

A fundamental factor for stability at high speeds is the machine’s structural integrity. Manufacturers use heavy-duty materials such as cast iron or steel alloys to build the frame and base. These materials absorb vibrations and reduce deflections that can occur when the saw blade and feed mechanisms move rapidly. Additionally, structural designs like dual-column supports or reinforced gantry frames help distribute mechanical forces evenly, preventing torsional stress that could destabilize the cutting process. The machine’s overall rigidity ensures that cutting precision is maintained even during continuous high-speed operation.

Precision Blade Tensioning and Guiding Systems

The behavior of the saw blade is another critical element impacting stability. High-speed cutting requires the blade to remain taut and correctly aligned. Automatic tensioning systems continuously monitor blade tension and adjust it as necessary to compensate for changes caused by heat or load. This prevents blade flutter or slipping, which can compromise cut quality and safety. Alongside tensioning, precision guides made from durable materials such as carbide or rollers stabilize the blade laterally, reducing vibration and wear. Together, these systems maintain blade tracking and reduce oscillations during rapid cutting cycles.

Advanced Control Systems and Sensor Feedback

Electronic control systems play an increasingly important role in maintaining stability at high speeds. Integrated sensors track parameters like blade speed, feed rate, and cutting force in real time. When the system detects anomalies—such as blade deflection or excessive load—it automatically adjusts operational variables to protect the machine and workpiece. Variable frequency drives and servo motors enable smooth acceleration and deceleration, reducing mechanical shocks that could affect stability. This closed-loop feedback control enhances not only precision but also safety by preventing conditions that could cause blade breakage or machine malfunction.

Effective Cooling and Lubrication

High-speed cutting generates significant heat, which can negatively affect machine components and blade performance. To address this, automatic band saw machines incorporate efficient cooling and lubrication systems. Coolants are delivered directly to the blade and workpiece interface to reduce friction and dissipate heat. This helps maintain blade sharpness and prevents thermal distortion of the workpiece. Proper chip removal through conveyor systems also prevents material buildup that could cause uneven feeding forces, which would destabilize the cutting process. Effective thermal management contributes to both operational stability and extended machine lifespan.

Regular Maintenance and Operator Expertise

Even the advanced machines require proper maintenance and skilled operation to maintain stability during high-speed cutting. Routine inspection of blade condition, guide alignment, and tensioning components ensures suitable performance. Operators trained in recognizing signs of instability—such as unusual vibration or inconsistent cuts—can intervene early to prevent damage. Calibration of sensors and periodic adjustments to the control system keep the machine functioning within safe and stable parameters. Ultimately, a combination of engineering well and informed operation ensures consistent high-speed cutting performance.

English

English русский

русский عربى

عربى