Email: hujin@chinahujin.cn

Performance of Angle Cut Band Saw on Varied Materials

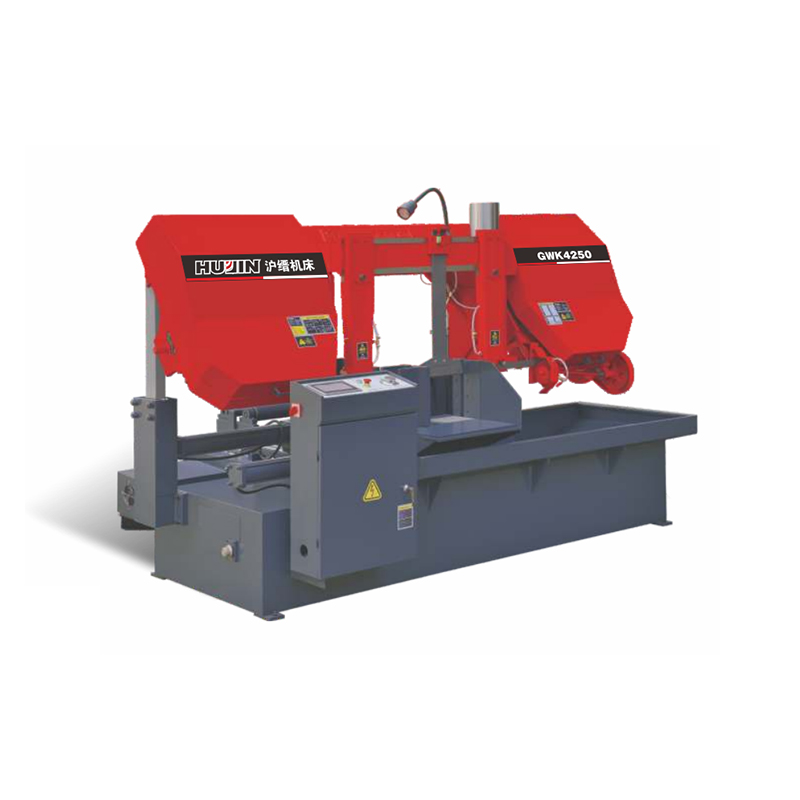

Introduction to Angle Cut Band Saw

An Angle Cut Band Saw is specifically designed to make precise angled cuts on a wide range of materials. Its versatility allows operators to cut metals, plastics, and composite materials at various angles while maintaining accuracy and surface quality. Understanding how the machine performs with different material thicknesses is essential for optimizing cutting efficiency and ensuring consistent results in production or workshop settings.

Effect of Material Thickness on Cutting Performance

Material thickness significantly impacts the cutting performance of an Angle Cut Band Saw. Thin materials generally allow higher cutting speeds and smoother surface finishes, as the blade encounters less resistance. In contrast, thick materials require slower feed rates, increased blade contact, and often more robust clamping to prevent movement during the cut. The machine’s ability to maintain blade stability and consistent feed pressure determines how effectively it handles varying thicknesses.

Blade Selection and Tooth Geometry

The type of blade used on an Angle Cut Band Saw plays a crucial role in cutting different thicknesses. Fine-toothed blades are preferable for thin materials to reduce burrs and achieve a clean finish. Coarser blades are better suited for thicker materials, providing faster material removal and reducing the risk of overheating. Additionally, the tooth geometry affects how efficiently the saw can cut through different thicknesses, influencing both the speed and quality of the cut.

Feed Rate and Cutting Pressure

Adjusting feed rate and cutting pressure is vital when working with materials of varying thicknesses. Thin materials require a lighter feed to prevent bending or distortion, whereas thicker materials need a more controlled, steady feed to maintain cutting stability and prevent blade deflection. Modern Angle Cut Band Saws often allow operators to adjust feed parameters easily, ensuring that each cut, regardless of thickness, meets precision requirements without compromising blade longevity.

Machine Rigidity and Stability

The structural rigidity of an Angle Cut Band Saw contributes directly to its ability to handle different material thicknesses. A stable frame and precision guide rails prevent vibration and blade misalignment, which are particularly critical when cutting thick or hard materials. Without sufficient rigidity, thicker materials can cause uneven cuts, blade wandering, or excessive wear, reducing both accuracy and efficiency. Maintaining the mechanical integrity of the saw ensures consistent performance across a range of material sizes.

Cooling and Lubrication Considerations

For thicker or harder materials, effective cooling and lubrication are essential to maintain performance. Coolants reduce heat buildup, minimize friction, and prevent premature blade wear. Applying proper lubrication not only prolongs the life of the blade but also ensures smoother cuts and improved surface finish, particularly on thick or high-density materials. Thin materials may require less intensive cooling, but consistent lubrication still improves overall efficiency and reduces the risk of material sticking to the blade.

The performance of an Angle Cut Band Saw varies depending on material thickness, but proper management of blade selection, feed rate, cutting pressure, and cooling ensures suitable results. Thin materials allow faster cuts and finer finishes, while thick materials require careful adjustment to maintain stability and precision. By understanding these factors, operators can improve the efficiency and accuracy of the Angle Cut Band Saw, making it a versatile tool for a wide range of industrial and workshop applications.

English

English русский

русский عربى

عربى